The Art and Science of Thermal Coloring for Pocket Watch Conversions

When it comes to restoring or converting vintage pocket watches, there is a delicate balance between preserving history and infusing new life into timeless pieces. One technique that beautifully bridges the gap is thermal coloring, an age-old process that not only enhances the aesthetic appeal of metal components but also provides protection against corrosion. For pocket watch conversions, thermal coloring adds a striking touch of color to previously uncolored metal, giving the watch a unique personality and enduring charm.

What is Thermal Coloring?

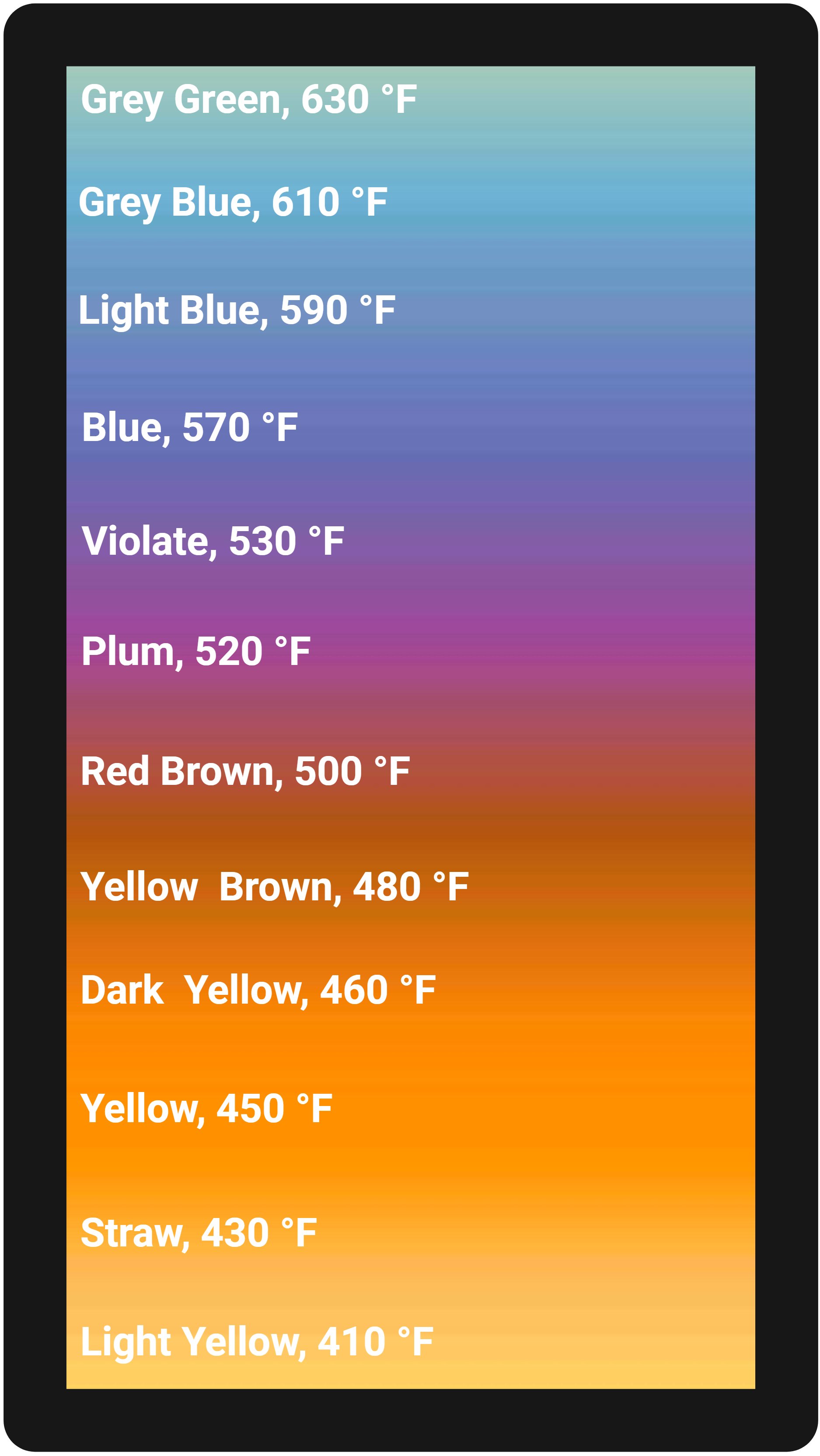

Thermal coloring, often referred to as "heat bluing," is the process of applying heat to steel or other metals, which results in a colorful oxide layer on the surface. This oxide layer can take on various hues depending on the temperature used, with colors ranging from light yellows to deep blues and violets. The process works by carefully controlling the temperature to achieve the desired color. For example, to achieve a traditional deep blue, the metal is heated to around 570 °F, while lighter yellow tones emerge at around 410 °F. The appeal of thermal coloring lies in the ability to create stunning visual effects while offering practical benefits, such as enhanced resistance to corrosion.

Color and corresponding temperature when thermally coloring.

Why Use Thermal Coloring?

Aesthetic Appeal: Vintage watches often feature uncolored or worn-down metal components that have lost their original luster. Thermal coloring can breathe new life into these pieces, adding vibrancy and an artisan touch. Whether it is a deep blue screw head or a striking plum-colored ratchet wheel, the possibilities are endless when it comes to color options and combinations. This personalization makes each watch unique, reflecting the skill of the craftsperson and the tastes of the wearer.

Protection from Corrosion: Beyond the aesthetic boost, thermal coloring also provides a protective layer. This oxide layer helps prevent rust and corrosion, which can otherwise damage the precision parts of vintage watches. By applying this layer, you extend the lifespan of these delicate components, ensuring they can be enjoyed for years to come.

Reversibility: One of the key advantages of thermal coloring is that the process is reversible. Unlike other treatments that permanently alter the watch’s components, thermal coloring allows the original metal to be restored if desired. This ensures that the watch is not permanently changed and can be returned to its original state, which is important for collectors where maintaining the watch's historical integrity is essential.

The Frett & Co Method

At Frett and Co Clockworks, we take pride in performing all our thermal coloring by hand, using traditional techniques that pay homage to the craftsmanship of vintage watchmaking. We heat our components over an open flame, and to achieve the desired colors, we use brass shavings to help control the heating process. Unlike some methods that rely on quenching (rapid cooling) to set the color, we heat our components extremely slowly, which allows for more precision and control over the final hue and ensures integrity of the component. Additionally, we do not apply finishing oils after thermal coloring. This choice preserves the raw beauty of the oxidized surface while still providing excellent protection against corrosion. The result is a pure and authentic finish that enhances the character of each watch.

How It's Done at Frett & Co

Thermal coloring requires precision and patience. The process typically involves:

Cleaning the Metal: Before applying heat, the metal components must be thoroughly cleaned to remove any oils, dirt, or residues that could affect the final color.

Controlled Heating: Using an open flame and brass shavings, the metal is heated slowly and evenly to ensure consistent coloring. The temperature is carefully monitored, as even a few degrees can drastically change the resulting hue.

No Quenching or Oil: After the desired color is achieved, we let the components cool naturally without quenching, preserving the beauty of the slow-heating process and ensuring durability of the component. Additionally, we do not apply finishing oils that can attract dust and change color, preferring to leave the natural oxide layer intact.

Pocket watch conversion with blue colored movement components. The blue color was achieved through thermal coloring at Frett & Co Clockworks.

Pocket watch conversion with plum colored movement components. The plum color was achieved through thermal coloring at Frett & Co Clockworks.

Pocket watch with gold colored movement components. The golden hardware is original (plated).

Final Thoughts

Thermal coloring is more than just a cosmetic treatment—it is a way to enhance and protect vintage watch components while preserving their history. For pocket watch conversions, it adds a layer of personal craftsmanship, turning each piece into a unique statement of both art and engineering. By using this technique, not only do you transform the appearance of the watch, but you also ensure it remains resilient against time and the elements.

Whether you are working on a vintage pocket watch or creating a conversion piece, thermal coloring offers a practical and beautiful solution for bringing metal components to life. And because the process is reversible, you can enjoy the beauty of colored components without permanently altering the watch’s heritage.